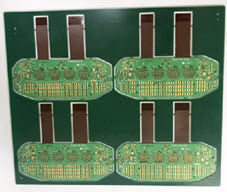

Products

Applications

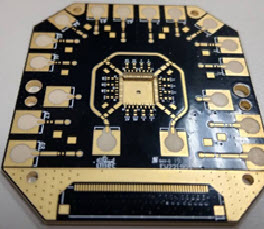

- 5G Products

- Data com

- Server

- Telecom

Main PCB Tech.

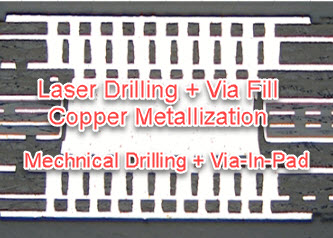

- HDI Process

- Blind / Buried Vias (Mechanical & Laser Drilling)

- Embedded Copper Coins

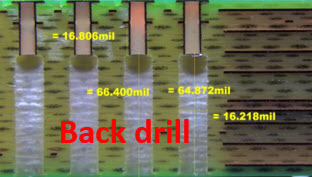

- Back drill

- Via-In-Pad (Resin Or Copper Paste Filled)

Capability

- Layer count: 6~40L

- Board material: Ro4350B、Ro4003C、M6 series 、M7 series、EMC528(HF)、EMC891~K、EMC890~890K(HF)、Isola I-Tera、Isola TerraGreen、Tuc-933、Tuc-883

- Board thickness: 0.18mm min.

- Size: 18" X 23" (Shipping size)

- BGA Pitch: 0.35mm (min)

- Min trace width/spacing: 0.003"/0.003"

- Min thru hole size: 6mils (VIP resin filled) 8mils (VIP copper paste plugged)

- Min gap from PTH to track inner layers: > 6mils

- Thru hole aspect ratio(The board thickness vs.Drill hole size): 8~30

- Min/Max Laser drill hole size: 3mils / 8mils ( VIP plated shut)

- Aspect ratio (dielectric thickness/ Laser drill hole size): 0.8Max.

- HDI: 9+N+9 (Anylayer)

- Back drill: Min hole size 15.7mils Depth tolerance +/-6mils

- Copper coin: length x width 3mm x 3mm(min) Surface flatness:30um(max)

- Layer to Layer Registration: +/-1.5mils min.

- Tolerance of impedance control: +/-5%

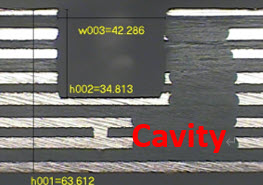

- Cavity Process: By LPKF laser cutting machine

- Board finishings: ENEPIG+Hard gold plating(Gold finger) Soft gold plating+Hard gold plating(Gold finger)

Applications

- High frequency High speed low loss

- High Dk Low loss

- Antenna test board

- Low Noise Block

- VSAT Transceiver

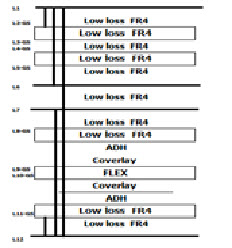

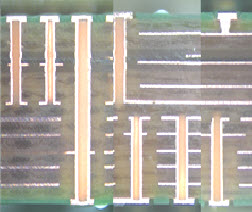

Main PCB Tech.

- HDI

- Blind/buried via (Mechical-drilled)

- Via-In-Pad (Resin Or Copper Paste Filled)

- Cavity Process

Capability

- Layer count: 2~20L

- Board material: Ro3003、Ro3010、RT5870、RT5880、RT6010、Ro4360、TMM10、TMM10i、TACONIC RF series、TACONIC TLY series、High frequency adhesive

- Double-sided process: RT5870、RT5880、RT6010、Ro4360、TMM10、TMM10i

- Hybrid: Ro3003、Ro3010、Ro4360、TACONIC RF series、TACONIC TLY series+ FR4

- Board thickness: 0.18mm(min)

- Size: 0.5" X 0.5" (min)(Shipping size)

- Min trace width/spacing: 0.005"/0.005"

- Tolerance of trace width / spacing: +/-8% trace width > 10mils and tolerance: +/-1mils

- Radius of Antenna width: 0.5mils(max)

- Min gap from Antenna to conductors: 3mils(min)

- Min thru hole size: 6mils (VIP resin filled) 8mils (VIP copper paste plugged)

- Min gap from hole edge to hole edge (Stitching via): 8mils

- Min gap from hole edge to copper (Stitching via): 6mils

- Aspect ratio: dielectric thickness / Laser drill hole size: 5mils / 6.50 mils(max) ( VIP plated shut )

- HDI: 1+N+1

- Layer to Layer Registration: +/-1.50 mils

- Tolerance of impedance contro: +/-5%

- Cavity Process: Lamination (Adhesive Low Dk Low Df)+depth control milling、LPKF depth control mill down

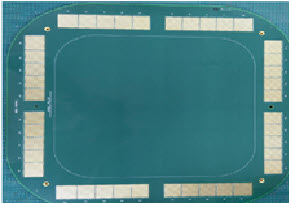

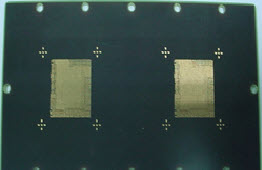

Applications

- High performance heat dissipation metal core

- LED

- Work Station Power Supply

- Base Station Transceiver

Main PCB Tech.

- Standard PCB process

- Cavity Process

Capability

- Layer count:

-

- Single-sided single layer MCPCB (Aluminum core or Copper Plates)

- Single-sided multi-layer MCPCB (Aluminum core or Copper Plates)

- Double-sided single layer MCPCB (Metal Core interlay) (Aluminum core or Copper Plates)

-

Board material:

- Thermal conductivity: Ventec VT-4A VT-4B

- Thickness: 2~6mils Thermal conductivity:2.2~7 (W/m*k)

- Aluminum core: 5XXX、6XXX

- Thickness: 0.8mm~3mm

- Copper Plates

- Thickness: 0.8mm~3mm

- Chip on Metal:

-

- Cavity Process: Lamination (nonflow Prepreg)+depth control milling、LPKF depth control mill down

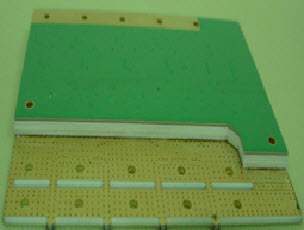

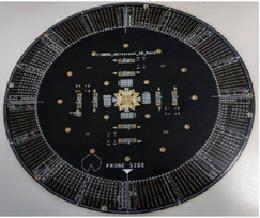

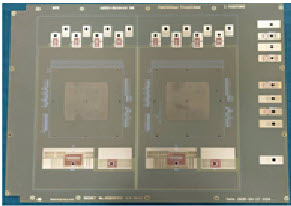

Applications

- Load Board

- Probe Card

Main PCB Tech.

- HDI Process

- Blind / Buried Vias (Mechanical & Laser Drilling)

- Back drill

- Via-In-Pad (Resin Or Copper Paste Filled)

Capability

- Layer count: 10~50L

- Board material: FR4 FR4-HTG or others

- Board thickness: 2mm~6.3mm

- Size: 18" X 23" (Shipping size)

- BGA Pitch: 0.35mm (min)

- Min trace width/spacing: 0.003" / 0.003"

- Min thru hole size: 6mils (VIP resin filled) 8mils (VIP copper paste plugged)

- Min gap from PTH to track inner layers: > 5mils

- Thru hole aspect ratio (The board thickness vs.Drill hole size): 8~30

- Min/Max Laser drill hole size: 3mils / 8mils (VIP plated shut)

- Aspect ratio (dielectric thickness / Laser drill hole size): 0.8Max.

- HDI: 9+N+9 (Anylayer)

- Back drill: Min hole size 15.7mils Depth tolerance +/-6mils

- Layer to Layer Registration: +/-3mils

- Tolerance of impedance control: +/-5%

- Warpage (Load Board / Probe Card): 4mil/inch / 1mils/inch

- Board finishings: Hard/Soft gold, ENIG

- Contersink: Y (θ: 82 degree, 90 degree & 100 degree)

- Conterbore: Y

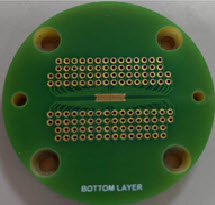

Applications

- Jedec/droptest/burn in

- Interposer

Main PCB Tech.

- HDI

- Blind/buried via (Mechical-drilled)

- Via-In-Pad (Resin Or Copper Paste Filled)

Capability

- Jedec/drop test/burn in

-

- Layer count: 2~14L

- Board material: FR4 FR4-HTG Polyimide (ARLON 85N、Ventec VT-90H) or others

- Board thickness: 0.9~2.0mm

- Size: 18" x 23" (Shipping size)

- Min thru hole size: 6mils (VIP resin filled)

- Min gap from PTH to track inner layers: > 5mils

- BGA Pad Size: 10mils(min) for Thru hole 6mils(min) for Laser-drilled

- Tolerance of BGA Pad size: +/-10%

- Gap between BGA PAD and solder mask opening: 1.2mils(min)

- Gap for BGA solder dam clearance:3mils(min)

- Layer to Layer Registration: +/-3mils

- Min/Max Laser drill hole size: 3mils / 8mils (VIP plated shut)

- Aspect ratio (dielectric thickness / Laser drill hole size): 0.8Max.

- Interposer

-

- Layer count: 2~14LL

- Board material: FR4 FR4-HTG Adhesive Polyimide

- Board thickness: 2.0~5.0mm

- Size: 6" x 6"(max) (Shipping size)

- BGA Pad pitch-0.15mm

- Min. BGA Pad size/spacing: 4/2mils

- Min Laser via size/deilectric thickness: 2/1.5mils

- Board finishing: ENIG

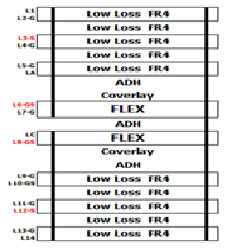

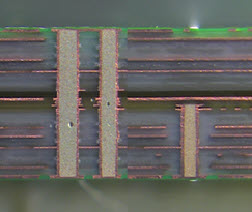

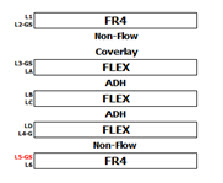

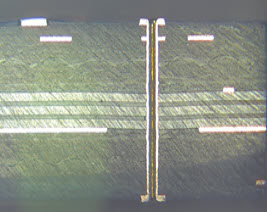

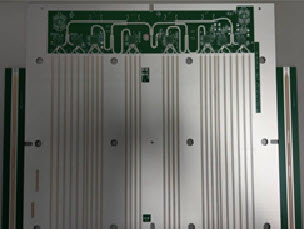

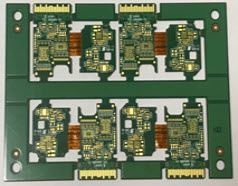

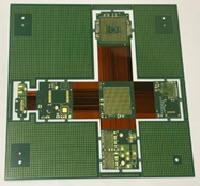

Applications

- Flex

- Rigid-flex board

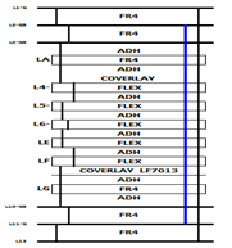

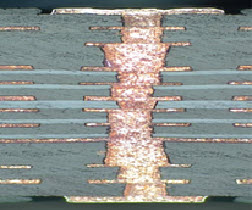

Main PCB Tech.

- HDI Process

- Blind / Buried Vias (Mechanical & Laser Drilling)

- Via-In-Pad (Resin Or Copper Paste Filled)

- Cavity Process

- Board finishings: Optional

Capability